Submerged Ultrafiltration for Sewage Treatment under Light and High Load Conditions

- Envirocleanse Solutions LLP

- Aug 26, 2025

- 3 min read

Introduction

Sewage treatment plants (STPs) are increasingly adopting submerged ultrafiltration (UF) membranes as a reliable and efficient alternative to conventional clarification and tertiary treatment methods. With growing concerns over water scarcity, stringent discharge norms, and the demand for safe water reuse, ultrafiltration technology has emerged as a preferred solution.

Submerged UF membranes, typically operating with a pore size of 0.03 µm to 0.1 µm, act as a robust physical barrier, effectively removing suspended solids, bacteria, colloids, and pathogens while ensuring consistent treated water quality. The adaptability of these membranes under both light load (low organic and solids loading) and high load (high BOD, COD, TSS, and shock loading) makes them highly valuable in modern wastewater management.

Working Principle of Submerged Ultrafiltration Membranes

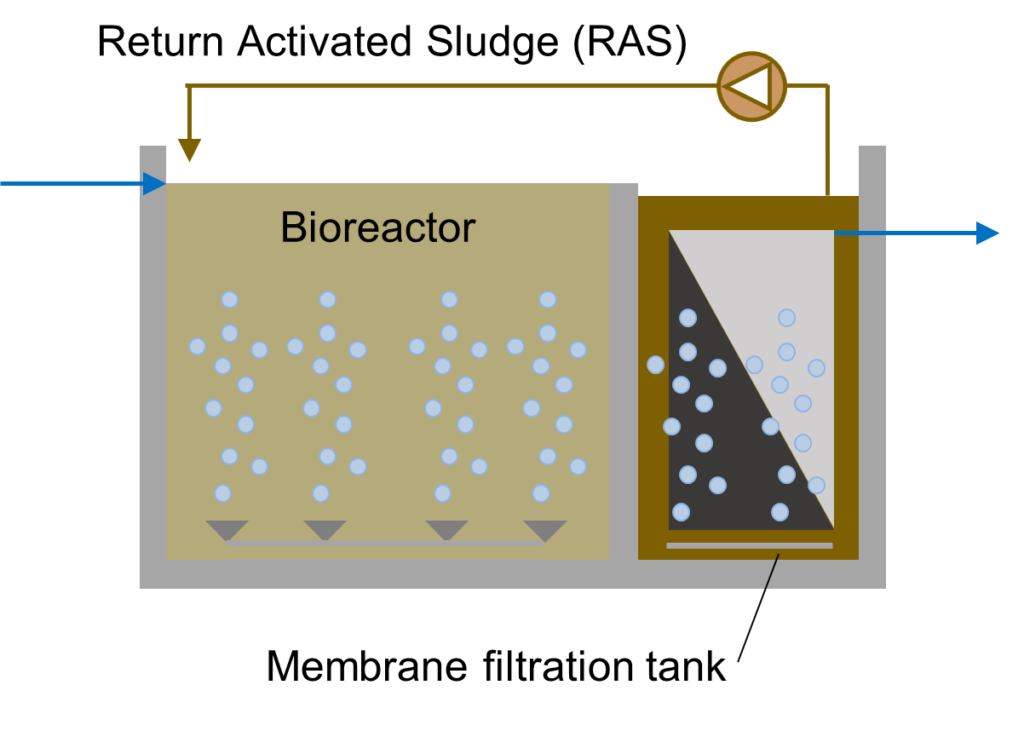

In submerged UF systems, membrane modules are directly immersed in the aeration tank or membrane tank. A low-pressure suction pump draws treated water (permeate) through the hollow fiber membranes, while aeration below the membranes provides scouring and minimizes fouling.

The pore size of 0.03–0.1 µm ensures removal of:

Total Suspended Solids (TSS)

Bacteria (including fecal coliforms)

Viruses (to a large extent)

Oil, grease, and fine particulates

Colloids and micro-flocs

This creates a clarified and disinfected effluent suitable for reuse in gardening, flushing, cooling towers, and even as feed for reverse osmosis (RO).

Submerged UF under Light Load Conditions

When sewage has relatively low organic load and suspended solids (for example, in residential complexes, IT parks, or institutions where wastewater is mainly domestic in nature), UF membranes perform with:

Stable flux: Low fouling tendency due to lower TSS.

Reduced chemical cleaning frequency: Membranes can run longer between clean-in-place (CIP) cycles.

Energy efficiency: Aeration and suction requirements are minimal.

Consistent water quality: Even under fluctuating influent flow, membranes deliver clear effluent.

Key Benefits in Light Load:

Lower OPEX due to reduced cleaning and aeration needs.

Extended membrane life.

Compact design due to smaller tank sizes.

Submerged UF under High Load Conditions

In municipal STPs, industrial effluents, or mixed sewage with high BOD, COD, and TSS levels, submerged UF membranes face higher challenges but are still highly effective.

Robust barrier performance: Even with heavy solids loading, membranes consistently reject particles >0.03 µm.

Enhanced aeration needs: Stronger air scouring is required to prevent clogging.

Frequent backwashing and CIP: Necessary to maintain stable flux.

Turbidity control: Effluent turbidity remains <1 NTU even under shock loads.

Pathogen removal: High rejection rates of bacteria and viruses ensure treated water safety.

Key Benefits in High Load:

Ability to handle variable influent quality.

Reliable compliance with discharge standards.

Acts as a protective barrier for downstream RO or polishing systems.

Membrane Characteristics (0.03–0.1 µm Range)

Nominal pore size: Ensures removal of fine colloids, bacteria, and most viruses.

Hydrophilic polymeric material: Provides high permeability and fouling resistance.

Outside-in flow configuration: Allows easy removal of solids during backwash.

Typical operating flux: 15–25 LMH (liters per square meter per hour), depending on load.

Cleaning process: Regular backwash + periodic CIP with sodium hypochlorite or citric acid.

Applications of Submerged UF in STPs

Residential and commercial complexes (light load)

Municipal sewage treatment (high load)

Industrial effluent treatment (textiles, food, pharma, etc.)

Water reuse projects (gardening, cooling towers, flushing)

RO pretreatment (to protect membranes from fouling)

Conclusion

Submerged ultrafiltration membranes with 0.03–0.1 µm pore size offer a highly reliable and sustainable solution for sewage treatment across both light and high load conditions. While light load systems benefit from lower energy and cleaning requirements, high load systems leverage UF’s robustness to consistently deliver high-quality effluent even under challenging conditions.

As water reuse becomes an integral part of sustainability strategies worldwide, submerged UF stands out as a versatile, eco-friendly, and future-ready technology for sewage treatment.

Comments